-

15000 ㎡

Cover an area

-

5000 ㎡+

Workshop

-

20 +

Processing equipment

-

100 Cities

Spread across the country

CHOOSE OUR STRENGTHS

-

Over 20 years of industry focus

Henan Yida Heat Exchange Equipment Co., Ltd. was established in 2000. It is a technology company that integrates scientific research, design, production, and sales of high-energy heat exchange equipment and energy-saving equipment. The company relies on universities such as Tsinghua University in Beijing and Xi'an Jiaotong University to focus on the optimization and technological upgrading of enterprise products, and provides cutting-edge technical support for the continuous development and growth of the company.

-

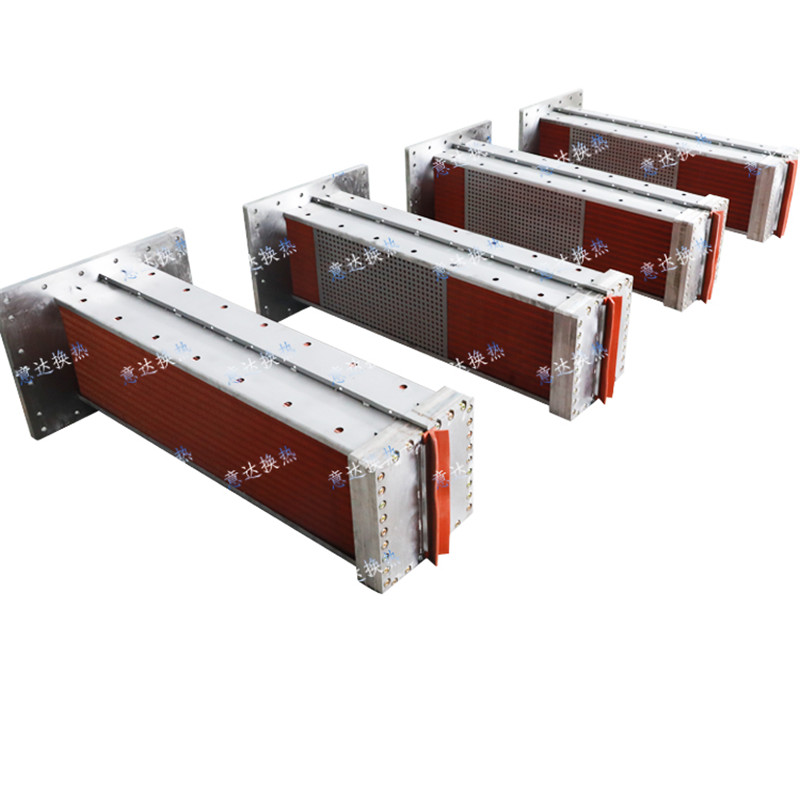

Complete product models

The company has successfully developed dozens of varieties and series of products such as intercoolers and final coolers of large air compressors of international famous companies such as Ingersoll Rand, Atlas, Sulzer, Demark, Cooper, Mann, Elliot, Sullair, Kobe Steel, Hitachi, etc.

-

Received unanimous praise from users

In recent years, the company has been continuously growing and strengthening, and its products have been exported to the Asia Pacific, North Africa, and Middle East regions since 2007. The company's products were once listed as trustworthy units for product quality by large domestic and foreign enterprises such as Sinopec Yanshan Petrochemical Branch, Tianjin Petrochemical Branch, PetroChina Lanzhou Branch, Shanghai Baosteel, China Steel Group, Air Liquide, and Messer Gas Company.

NEWS CENTER

-

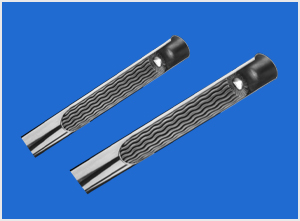

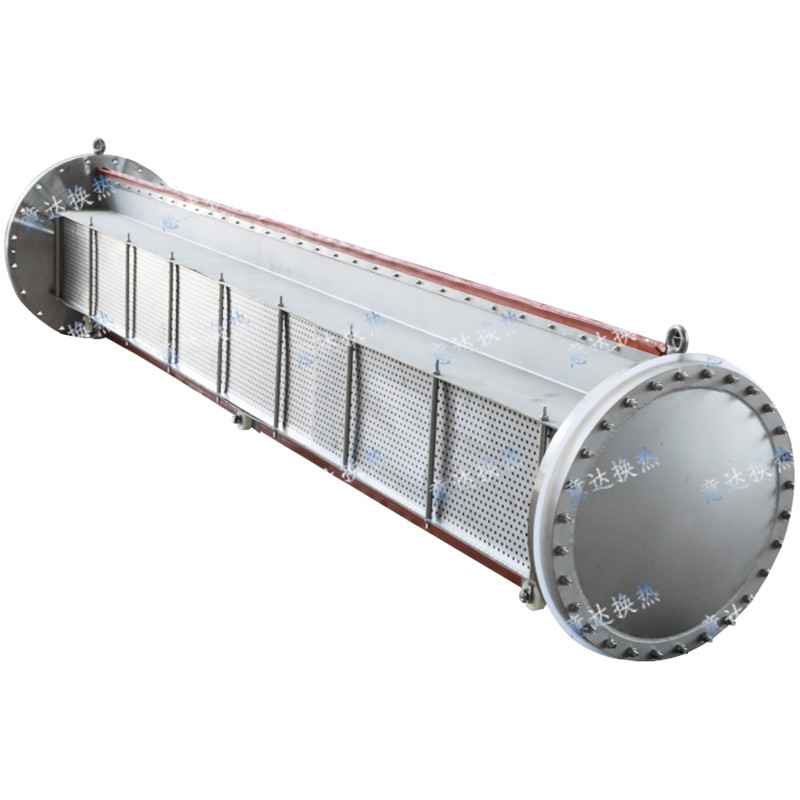

The sleeve heat exchanger used by Atlas has obvious advantages

06-30Atlas air compressor G series is a screw compressor, of which GR is a two-stage compression, oil injection screw compressor, and the supporting interstage cooler is a jacketed heat exchanger, which is widely used in air conditioning, refrigeration, chemical and other industrial fields. In order to save energy, slots are often opened on the surface of flat fins or corrugated plates are used to enhance heat transfer, mainly including flat fins, slotted fins, triangular corrugated fins, and sinusoidal corrugated fins. At present, the air coolers used in domestic industries such as refining, chemical, and power are developing towards * * and compactness. For many years, the air coolers used in these industries have mostly been wound or bimetallic rolled plates. Compared with traditional wound and rolled plates, the sleeve plate has a larger fluid flow resistance outside the tube, but its structure is compact, mechanical vibration is light, airflow is uniform, and heat transfer effect is greatly improved. Therefore, the sleeve plate has gradually eliminated traditional fin types and is increasingly used in gas-liquid heat exchange applications such as air coolers.

-

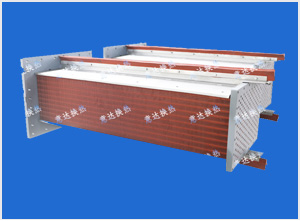

Cooper cooler - excellent performance

06-30The inlet and outlet of the Cooper cooler water filter are designed as an upper and lower split, which not only prevents direct impact of water pressure on the filter screen, but also changes the situation of blockage caused by debris staying away from the discharge outlet during aggressive filter screen filtration. When discharging, several filter chambers need to be cleaned one by one, which often leads to blockage. The material and structure of the mesh board greatly improve the flow area of the water, effectively reducing the water resistance of the filter screen, ensuring reliable operation without jamming, blockage, or blockage, and greatly extending the filter screen. Using 2-8mm stainless steel plate for stamping and forming, the mesh core can withstand a differential pressure of 150kPa without deformation or damage. It has the characteristics of long working life, corrosion resistance, no rust, smooth appearance, and no scaling. Cooper coolers are very popular in future applications and daily life. Water enters the water filter through the lower inlet, and when impurities in the water pass through the mesh core, they are trapped on the mesh core due to their larger volume than the mesh core holes. When they accumulate to a certain amount, a certain pressure difference is formed at the inlet and outlet. The precision and diameter of the filter screen vary, and the pressure difference is also different. Scroll one step every 10-30 seconds, with the handle pointing towards each recess and fixed until it rotates once, closing the drain valve and completing manual drainage.

-

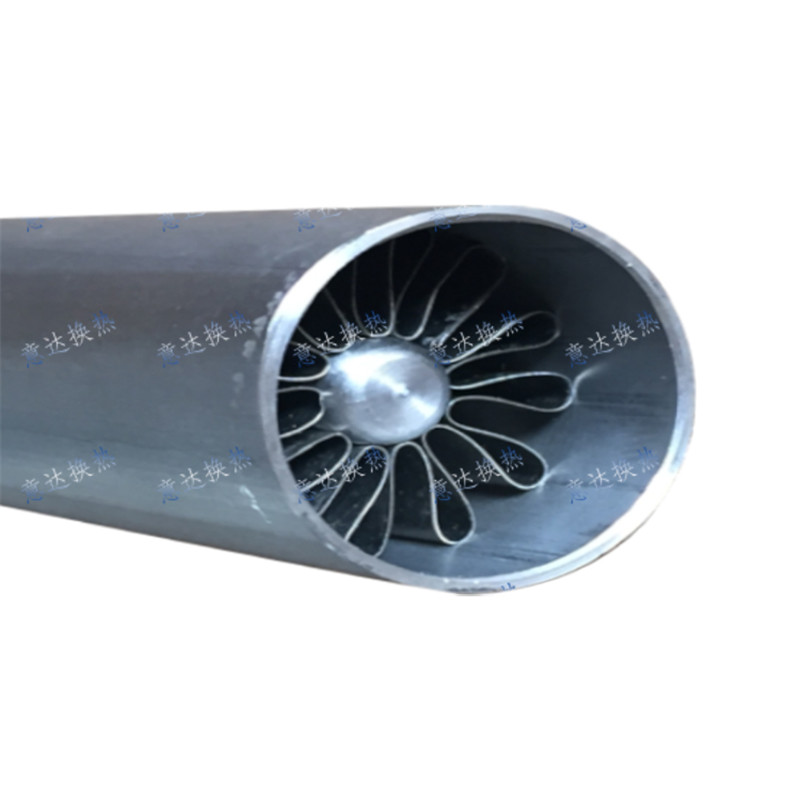

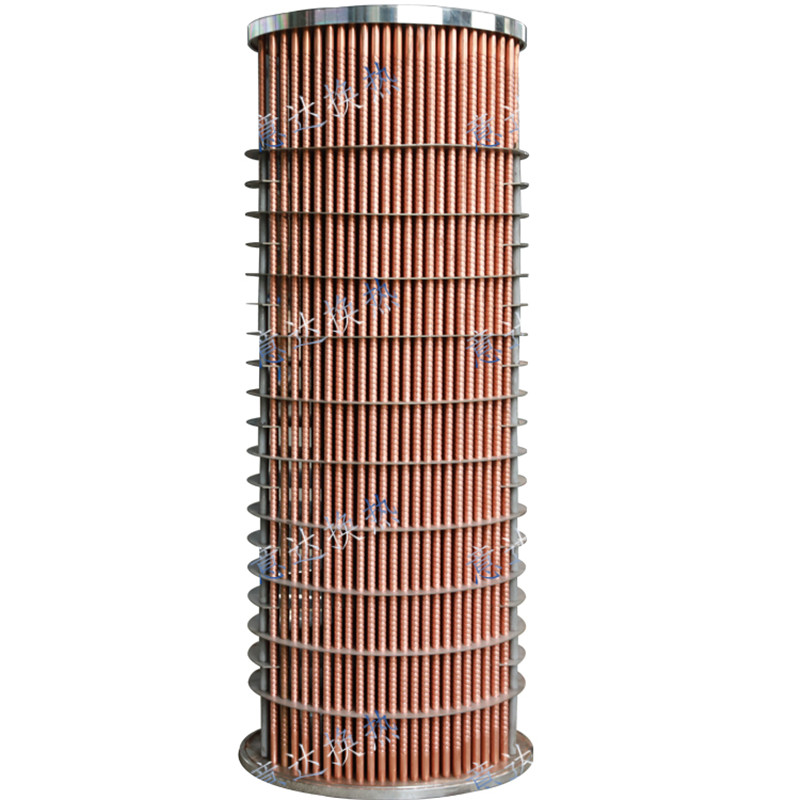

Stainless steel inner finned tube - safety above all else

06-30Stainless steel inner finned tubes are uniformly distributed with spiral electric heating alloy wires (nickel chromium, iron chromium alloys) along the axial direction of the inner base of the tube. The empty space is filled and compacted with magnesium oxide sand with good insulation and thermal conductivity. The ends of the tube mouth are sealed with silicone or ceramic. This metal armored electric heating element can heat air, Shanghai Xu Electronics waste heat recovery device metal mold, and various liquids. Stainless steel single head electric heating tube is made of metal tube as the outer shell. According to the different application states, safety and equipment requirements of the electric heating tube, the electric heating tube of the Hangzhou oxygen concentrator cooler will also include sealing structures, terminal structures, flanges, temperature control or safety wires and other structures. Stainless steel single head electric heating tube is made by placing an electric heating element in a metal tube, filling it tightly with crystalline magnesium oxide powder with good heat resistance, thermal conductivity, and insulation properties in the Qingjiang Petrochemical oil cooler, and processing it with other technologies. It has the characteristics of simple structure, high mechanical strength, high thermal efficiency, safety and reliability, simple equipment, and long service life. Widely applicable to various equipment such as saltpeter tanks, water tanks, oil tanks, acid alkali tanks, melting furnaces for easily melted metals, air heating furnaces, drying furnaces, drying ovens, hot pressing molds, etc. Uniformly distribute spiral electric heating alloy wires along the axial direction of the base inside the pipe.

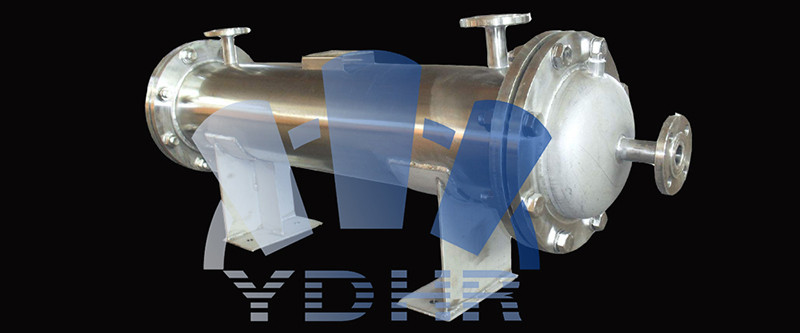

ABOUT US

ABOUTHenan Yida Heat Exchange Equipment Co., Ltd. was established in 2000. It is a technology company that integrates scientific research, design, production, and sales of high-energy heat exchange equipment and energy-saving equipment. The company relies on universities such as Tsinghua University in Beijing and Xi'an Jiaotong University to focus on the optimization and technological upgrading of enterprise products, and provides cutting-edge technical support for the continuous development and growth of the company. After more than ten years of hard work, our company has successfully developed dozens of varieties and series of products such as intercoolers and final coolers of large air compressors from internationally famous companies such as Ingersoll Rand, Atlas, Sulzer, Demark, Cooper, Mann, Elliott, Sullair, Kobe Steel, Hitachi, etc. The company's marketing network covers more than 100 units across the country, as well as many well-known foreign enterprises. These products have been validated by numerous large and medium-sized enterprises at home and abroad, and their various parameters have met the design and usage requirements of similar foreign products, receiving unanimous praise from users. In addition, in recent years, enterprises have been continuously growing and strengthening, and their products have been exported to the Asia Pacific, North Africa, and Middle East regions since 2007. The company's products were once listed as trustworthy units for product quality by a large number of large domestic and foreign enterprises such as Sinopec Yanshan Petrochemical Branch, Tianjin Petrochemical Branch, PetroChina Lanzhou Branch, Jinzhou Branch, Shanghai Baosteel, China Steel Group, Air Liquide, Messer Gas Company, etc. In early 2005, the company successfully passed the ISO9001 international quality system certification and was rated as a "product quality trustworthy unit" by the Provincial Quality Supervision Bureau. The company covers a total area of over 10000 square meters, with a production plant of over 2000 square meters. It has three Hanchuan XH716 machining centers, four CX6142 CNC lathes, and more than 20 processing equipment including various models of ordinary lathes, milling machines, grinders, planers, drilling machines, etc. The company currently has 86 employees, including 3 engineers, 8 design and development personnel, with 36% of them holding a bachelor's degree or above.

MORE

+

+